I had a short flight up to Rock Hill, SC Sunday to Skytech Inc., the Piper Service Center there, for my plane’s annual inspection. I had planned to take it up before Thanksgiving but we had several days of bad rainy weather, so the trip was pushed back to the last day I could legally fly the plane before its annual inspection. The last annual was done in November and so expired on Sunday, November 30.

I had a short flight up to Rock Hill, SC Sunday to Skytech Inc., the Piper Service Center there, for my plane’s annual inspection. I had planned to take it up before Thanksgiving but we had several days of bad rainy weather, so the trip was pushed back to the last day I could legally fly the plane before its annual inspection. The last annual was done in November and so expired on Sunday, November 30.

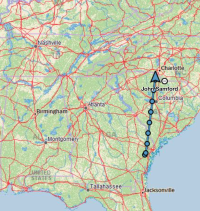

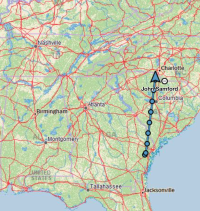

The trip up was delightful with perfect weather and a strong tailwind that had me clipping along at 155 knots. The trip was only one hour 20 minutes. Rock Hill is just south of Charlotte so I hopped a non-stop flight back to Savannah yesterday.

This will be a fairly major inspection as it is the standard annual plus the plane is just coming up on 1,000 hours of total flight time. There are a number of optional but recommended inspections due now, and several optional items that the previous owners opted not to do along the way. I am getting many of these done except those that I am advised are “ridiculous”. In aviation, the manufacturers must use a CYA mentality of recommending everything, so a considerable degree of investigation is needed to sort the prudent from the stupid inspections. The service center emailed me the following list yesterday from which we are picking and choosing. The number before each item is the number of hours for that project:

2.0 - 400hr Inspect Airborne Pressure Manifold

1.0 - 400hr G243 Battery Cap Check (400hr/1 yr)

8.0 - 400hr Valve/Rocker Inspection

N/C - 500hr Replace Central Instrument Air Filter (500hr/1yr)

3.0 - 500hr Desludge Propeller and Crankshaft

16.0- 1000hr Replace Engine Fluid Hoses (Except for Type D)

4.0 - Propeller Overhaul (2400hr/6 yr)

0.5 - 30day Battery Compartment Inspection

0.5 - 30day Portable Fire Extinguisher Inspection

0.5 - 30day Test ELT

N/C - 90day Check Hydraulic and Brake Fluid

N/C - 90day Clean Fuel Filter

0.5 – 6mos Lube Propeller

2.0 – 12mos Perform Capacity Test of Standby Attitude Indicator Battery

2.0 - 12mos Inspect 1H5 Manifold Check Valve per Airborne SL 39A (after 5yrs from mfg date)

2.5 - 72mos Replace Aero Accessories Vacuum Pump Shear Coupling

15.0- 7yr Perform Detailed Cabin Inspection

5.0 – 7yr Remove Inboard Metal Fuel Tanks and Inspect for Corrosion per 28-10-00

4.0 – Replace fuel tanks Flexible Hose Interconnect Couplings and Vent Hoses Each 7yrs TIS

The big detailed cabin inspection, replacing all engine hoses, and the valve rocker inspection all add up to 39 hours of pretty high-priced labor and none of these need to be done right now. So I believe I will get a good bit of the work done and have a safe plane with my pocketbook reasonably intact.

I realize I haven’t been posting here, and I’m looking forward to some more flying adventures and more blogging. We are reasonably finished now completing our move to live in Richmond Hill, Georgia, so I should have some more time on my hands for flying.

Tuesday, December 2, 2014 at 08:23AM

Tuesday, December 2, 2014 at 08:23AM  I had a short flight up to Rock Hill, SC Sunday to Skytech Inc., the Piper Service Center there, for my plane’s annual inspection. I had planned to take it up before Thanksgiving but we had several days of bad rainy weather, so the trip was pushed back to the last day I could legally fly the plane before its annual inspection. The last annual was done in November and so expired on Sunday, November 30.

I had a short flight up to Rock Hill, SC Sunday to Skytech Inc., the Piper Service Center there, for my plane’s annual inspection. I had planned to take it up before Thanksgiving but we had several days of bad rainy weather, so the trip was pushed back to the last day I could legally fly the plane before its annual inspection. The last annual was done in November and so expired on Sunday, November 30.

Reader Comments